Services > Field Testing > Bulk Electroluminescence (EL) Testing

Bulk Electroluminescence (EL) Testing

-

-

-

IV curve tracing

-

Milestone verification

High Volume EL testing

While solar PV is a proven technology with huge potential upsides for investors, the manufacturing side of the industry is still relatively young, meaning any number of issues can affect the quality of the modules during the manufacturing phase.

Short innovation cycles lead to ever new technologies arriving with limited reliability testing done before market entry, making it a challenge for anyone without expert guidance to source top-quality modules on a consistent basis.

With a global presence, Intertek CEA can bring its technology to you, wherever you are. Our AI-supported analytics are central and based on decades of EL testing experience.

Why is onsite EL testing so important?

Commissioning and warranty claims

Due diligence on existing assets

Insurance documentation

Degradation monitoring

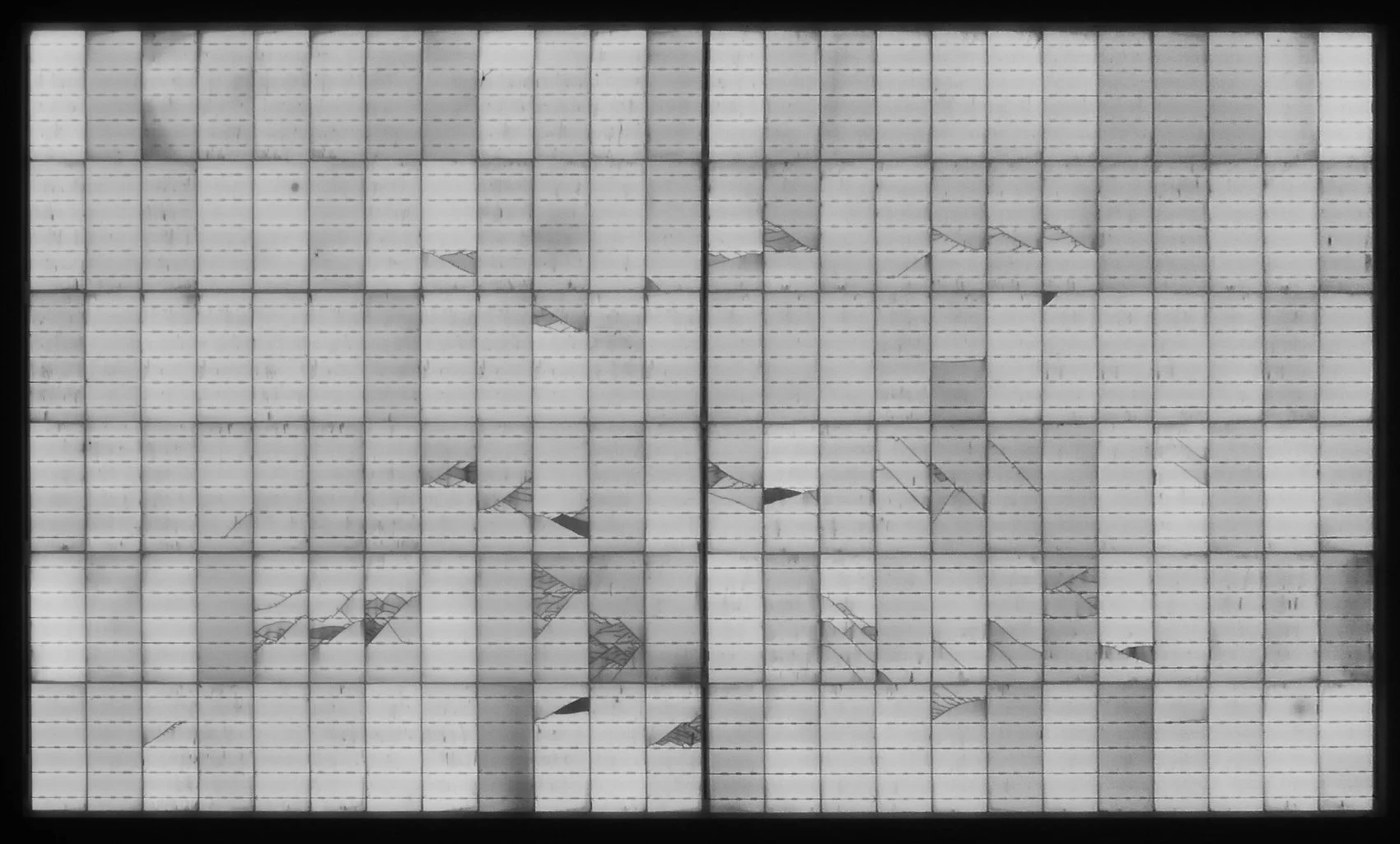

Comprehensive Electroluminescence (EL) Testing Plan Reduces Your Risk of Underperformance

Non-disruptive Process

On installed modules, testing takes place at night so that production is not disrupted. Independent of weather and irradiance. Safe operation due to system being offline.Efficient Sampling Strategy or High-Volume Testing

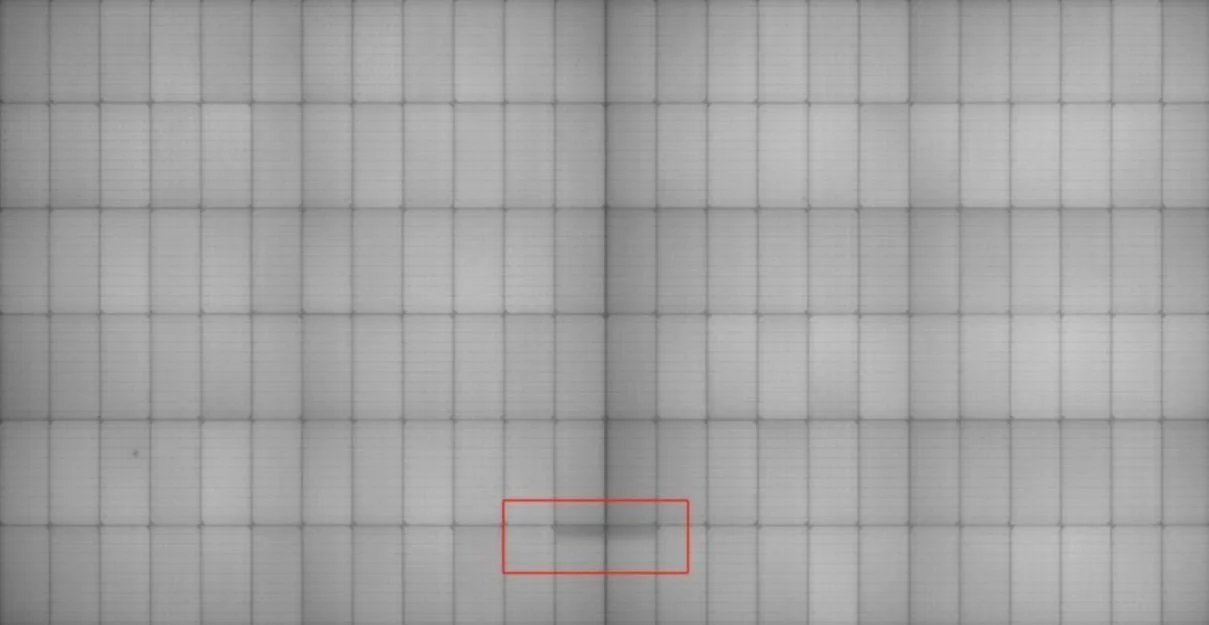

Intelligently planned sampling procedures ensure we’re testing just enough modules to give you the information you need. But we can test them all, if needed.Robust Quality & Analysis of Images

Intertek CEA takes lab-quality images to utility scale assets.

AI-based analytics can utilize client-specific inspection criteria.

Why Intertek CEA?

Lab-Quality at Utility Scale

Advanced String Powering

Connect full strings, full combiner boxes, or plug directly into the inverter. Proprietary equipment and streamlined processes enable seamless switching through the system and powering of modules for testing during inspection.

Drone EL Inspection

Unique lift-off technology: Drones equipped with specialized EL cameras and auto-detection capabilities capture sharp images from streaming video, enabling high-volume inspections even in challenging environments such as floating PV systems, facades, rooftops, and swampy terrain or mountainous area.

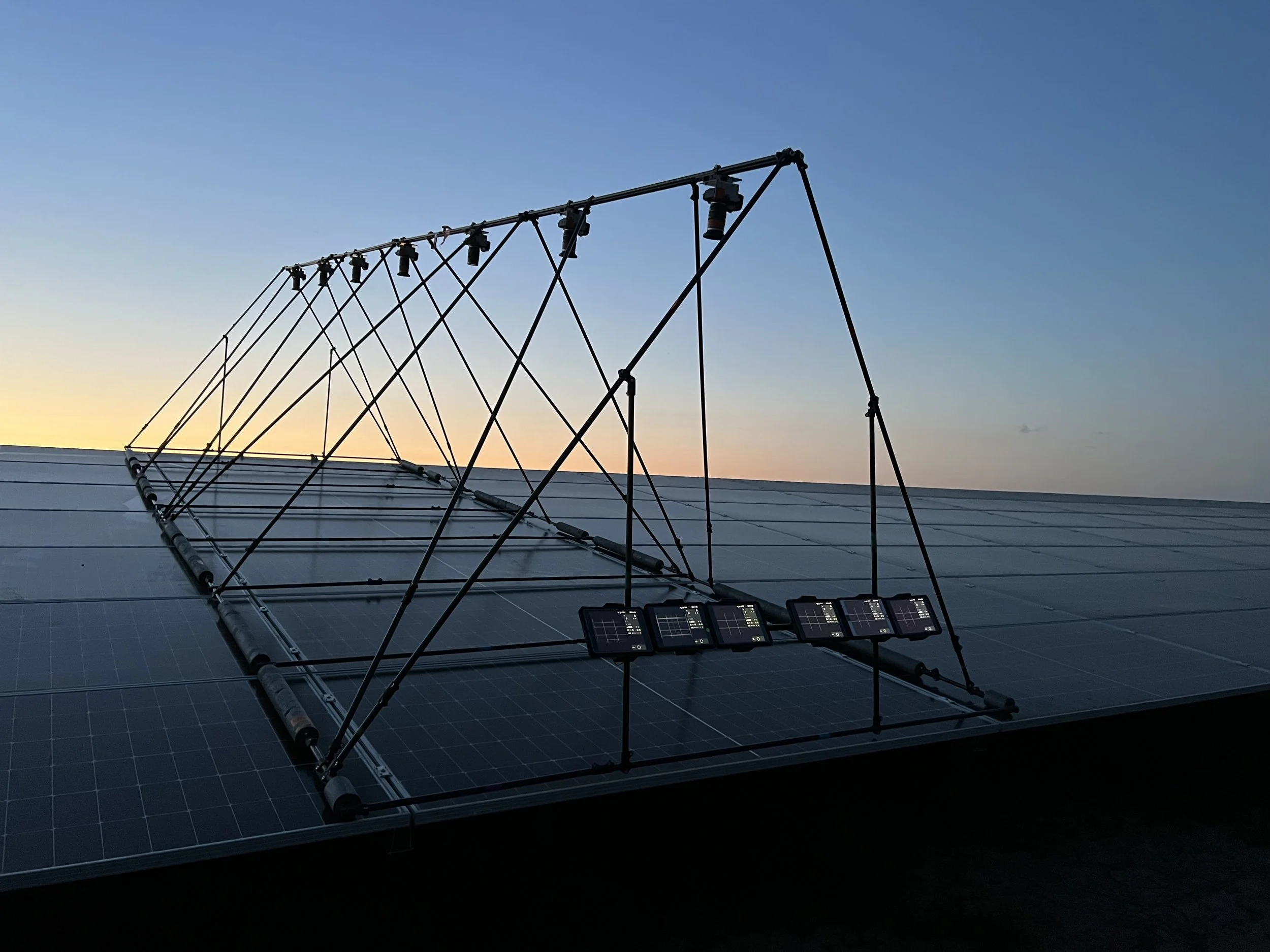

Multi Camera Tripods

Depending on the site layout, drones may not always be the fastest solution. Instead, Intertek CEA may utilize lightweight multi-camera systems that can process thousands of high-resolution images per hour.

AI-Powered Processing

We leverage EL images assessed during QA work at PV module factories around the globe.

We have decades of experience in EL image analysis.

We train our AI using specific anomalies and apply project-specific classification criteria.

When To Perform the Testing

Commissioning and Warranty Claims: Compare factory, post-shipment, and on-site EL images to pinpoint responsibility and support claims.

Due Diligence: Reveal hidden issues before asset acquisition or refinancing. Representative sample of full site inspection.

Insurance Documentation: Capture evidence post storm or hail with precision imaging techniques and reliable classification of the defects.

Degradation Monitoring: Perform repetitive inspections to track defects over time to proactively manage risk.

Have a Question or Need Assistance?

-

Bulk Electroluminescence (EL) Testing

IV curve tracing

Milestone verification