Electroluminescence (EL) Testing as a Quality Assurance Tool

pv magazine Roundtables USA on Electroluminescence (EL) Imaging as a QA Tool

pv magazine Roundtables USA’s Session 1, “Optimizing Solar Systems & Hardware”, included a presentation by CEA’s Senior Project Manager/Solar Engineer, Claire Kearns-McCoy, on the importance of using EL imaging to ensure the quality of your PV modules.

Claire explains how EL image testing detects issues that are frequently found at various points in the PV module lifecycle, from the factory to the field. She highlights that EL testing is a critical piece in preventing module underperformance over the lifetime of a solar project.

As solar deployments continue to grow, so do the risks of module failures, underperformance, and safety hazards—many of which are preventable with the right knowledge. In this Solar Power World webinar, Intertek CEA Senior Engineering Managers Claire Kearns-McCoy and Ankil Sanghvi explain how understanding common pitfalls—from thermal events to electrical failures—can help developers avoid millions in losses.

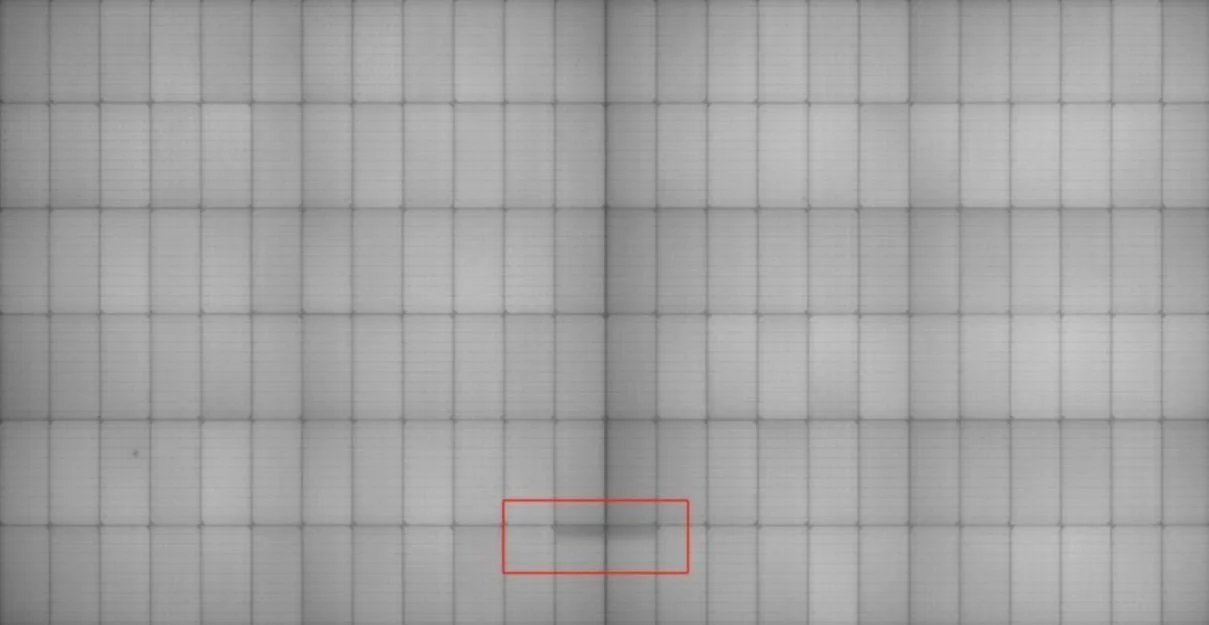

CEA conducted factory, pre-installation, and post-installation inspections for 1 GW solar PV portfolio in Chile. The goal was to assess module quality and identify defects from manufacturing to installation. The inspections focused on electroluminescence (EL) imaging and visual inspection to detect potential soldering issues, microcracks, and other module degradation mechanisms. A total of 8,520 images were taken.

In this PV Tech article, Paul Wormser, Vice President of Technology, and Jake Edie, Vice President of Marketing, discuss the prevalence of soldering defects in solar panels, their impact on performance, and how robust quality assurance measures can help mitigate these risks.

In this webinar hosted by the American Solar Energy Society's PV Technical Division, CEA's Engineering Manager Claire Kearns-McCoy discusses solar PV module quality risks.

CEA’s Vice President of Marketing, Jake Edie, recently wrote an article in Renewable Energy World about the most surprising findings in clean energy and what developers and buyers will be watching most closely as 2024 unfolds.

After years of improving quality standards, solar cell cracking appears to be on the rise again, perhaps due to new manufacturers entering the sector. Clean Energy Associates’ (CEA) senior engineering manager Claire Kearns-McCoy considers ways to stop the rot.

Intertek CEA's extensive field research unveils the hidden threats in solar PV modules, emphasizing the critical role of Electroluminescence (EL) testing in detecting unseen damages. Our findings highlight the lifecycle of module defects, the surge in microcracks, and the pivotal importance of visual inspections in identifying issues often missed by other methods.

While performing PV module electroluminescence (EL) inspections in the field, a new type of microcrack associated with new module and cell technologies has been spotted. They are known as edge ribbon cracks, and have been seen to grow during shipping and installation. CEA’s Claire Kearns-McCoy and George Touloupas offer a closer look.

pv magazine Roundtables USA included this presentation by CEA’s Senior Project Manager/Solar Engineer, Claire Kearns-McCoy on the importance of using EL imaging to ensure PV module quality.

Improper installation and handling procedures can result in significant PV module damage. The combination of EL and visual inspections can provide details about the origins and severity of module damage.