From Standards to Sandstorms

by Jörg Althaus & Huatian Xu

This article was originally published in pv magazine - December 2025 Edition.

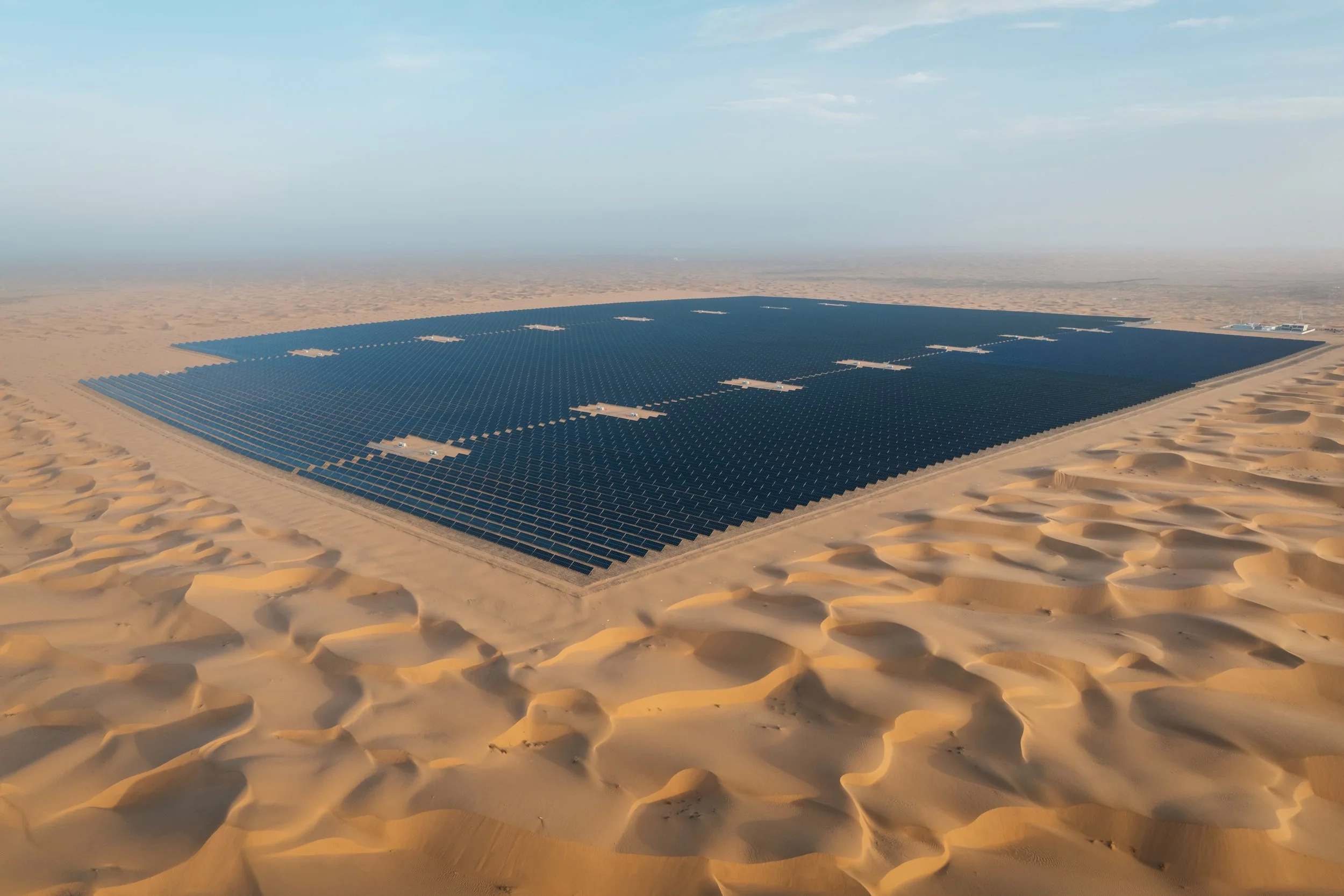

The Middle East now ranks among the world’s most ambitious solar markets. Gigawatt-scale projects across Saudi Arabia, the United Arab Emirates, and Egypt are supported by national programs that pair large tenders with local-content incentives aimed at onshoring production. Yet the same geography that powers the region’s solar boom challenges developers in unique ways, write Intertek CEA experts Jörg Althaus and Huatian Xu.

Solar development in the Middle East increasingly intertwines with industrial policies. Saudi Arabia and the UAE push to localize the majority of their PV supply chain through public-private partnerships and local-content requirements. This process is moving quickly. Production of polysilicon, wafers, cells, modules and key balance-of-system components is already local or planned within two years. This creates opportunities but also introduces new variables. Local assembly lines continue to ramp up, while imported modules still dominate early deployment phases. This mix of sourcing raises the stakes for verification. Developers must confirm that every component delivers consistent reliability regardless of origin. As regional manufacturing expands, lab testing and market intelligence data from Intertek CEA show that process variability during factory ramp-up can significantly affect module reliability, reinforcing the need for region-specific quality benchmarks.

Climate stress

Desert conditions impose unique mechanical and chemical stresses on PV systems. Standard IEC 61215 and 61730 tests provide a baseline, but they were written for moderate climates, not for sites where module surfaces can exceed 70 C or where UV exposure lasts year-round. Temperatures above 45 C exceed standard test limits, accelerating material fatigue and electrical decay. High ultraviolet exposure ages polymer backsheets, junction boxes, and cable insulation. Dust compounds the challenge by dimming output through soiling, while physically abrading glass and coatings. Windborne sand scratches surfaces and gathers around seals, creating micro-gaps that weaken insulation. Performance declines steadily, often beyond the reach of routine cleaning. Coastal deserts add corrosion risk for racking components. Intertek CEA’s field monitoring and technical due diligence across desert-climate PV sites show that elevated heat and irradiance accelerate multiple degradation modes, including potential-induced degradation (PID), light-induced degradation (LID), and light- and elevated-temperature- induced degradation (LeTID). These effects vary with cell technology and ambient temperature. Developers who integrate such climate-adjusted loss factors early achieve performance models that align more closely with measured realities.

System design

“Additional heat lowers voltage and accelerates wear”

Module reliability draws much of the spotlight, but system design choices determine whether those modules perform as intended. In desert environments, elevated temperatures, abrasive dust and relentless ultraviolet exposure stress every part of a photovoltaic system, from racking and cabling to inverters and tracking motors. Modules operate hotter in desert climates because convective cooling drops and ambient air temperatures stay high through most of the day. That additional heat lowers voltage and accelerates wear. Developers can mitigate these effects by widening row spacing, adjusting tracker stow angles, and elevating mounts to limit heat re-radiation from the ground. Cabling and connectors also merit scrutiny. Heat, UV, and dust degrade insulation and raise contact resistance. Using UV-stabilized polymers, verifying ingress-protection ratings, and tightening quality control on sealing and crimping processes extend service life in such harsh conditions. Power electronics face similar pressures. Dust clogs cooling filters or sneaks through small leaks, triggering thermal shutdowns or corrosion. Passive cooling designs and dust-tested enclosure seals extend uptime and reduce maintenance demands. No single measure eliminates all these location-specific risks, but a system-level approach can help bring the risks under control. Developers who evaluate how local conditions interact with component choices, rather than treating each in isolation, can hope to sustain higher energy yield and lower operation and maintenance (O&M) costs over time.

Quality assurance

In the Middle East, where temperature and radiation extremes can magnify even minor flaws, quality assurance (QA) turns into a site-specific discipline. The goal isn’t to replace global standards but to apply them thoughtfully to environments beyond their traditional assumptions. An effective QA program for desert projects starts before procurement. Specifications should reference testing for high temperature, abrasion, and UV durability beyond baseline IEC 61215 and 61730. Suppliers should not only deliver certificates but also field and laboratory data to demonstrate that modules and components will perform and maintain their electrical and optical stability under the relevant stressors. Recent laboratory analyses corroborate findings from desert- field inspections. Early-stage degradation occurs faster in high-temperature regions, underscoring the importance of testing beyond standard IEC baselines. The IEC TS 63126 standard, which expands testing for high-temperature and high-irradiance environments, provides a valuable benchmark but remains underused across much of the industry. Independent factory audits and factory- acceptance testing form the next layer of protection. In emerging manufacturing markets, these steps confirm that new production lines achieve process maturity and consistent workmanship. Once modules and components reach the field, inspections and early O&M evaluations close the loop. Visual checks catch coating wear, corrosion, or early polymer discoloration before those issues affect performance. Standard tests underrepresent desert stresses, so some buyers request accelerated lab simulations that mimic local cleaning and abrasion. Linking QA data across all stages from factory to field exposes where defects originate and clarifies accountability between the integrator, shipper, and EPC. This staged QA process builds traceability and evidence that components can handle the environment. In a market where high temperatures and abrasive cleaning can turn small oversights into systemic failures, traceability safeguards asset value.

Desert durability

Desert sites rank among the harshest testing grounds. Heat, dust, humidity, and high irradiance magnify every weakness in materials and workmanship. Field inspections in desert environments confirm that performance ratios decline more steeply during the first operational year than in temperate climates, emphasizing the value of localized durability testing. But nearly constant sunlight ensures that systems built to endure these tough conditions offer enormous potential for solar generation. That shift begins with mindset. Instead of designing from the product catalog outward, developers and EPCs can design from the environment inward. Localized testing and long-term performance data help teams prioritize durability before chasing efficiency gains. Doing so will strengthen the region’s broader energy ambitions. Reliable systems cut lifecycle costs, reduce downtime, and build investor confidence in largescale deployment. Over time, those gains can underpin a new phase of regional manufacturing – one focused not only on volume, but on producing equipment tailored for Middle Eastern conditions. Developers who embrace that principle will lead a generation of solar plants that deliver consistent, bankable performance long after the dust settles.

Jörg Althaus leads Intertek CEA’s quality assurance and engineering activities across Europe. Previously with TÜV Rheinland, he managed global solar and storage expert teams and contributed to global PV standards under IEC Technical Committee 82 and the IECEE CB scheme. Althaus is based in Cologne, Germany, and participates in SolarPower Europe and the Solar Stewardship Initiative.

Huatian Xu has developed and led Intertek CEA’s quality assurance programs since joining the company in 2012. He oversees PV module qualification protocols, advises clients on equipment specifications, and tracks global trends in technology performance and supply chain dynamics. Xu also manages supplier relationships with major PV and inverter manufacturers including Longi, JA, Jinko, Trina, Sungrow, Huawei, and Solis.