Services > ESG & Traceability > Supply Chain Traceability

Traceability Audits for PV and BESS Components

Supply Chain Traceability

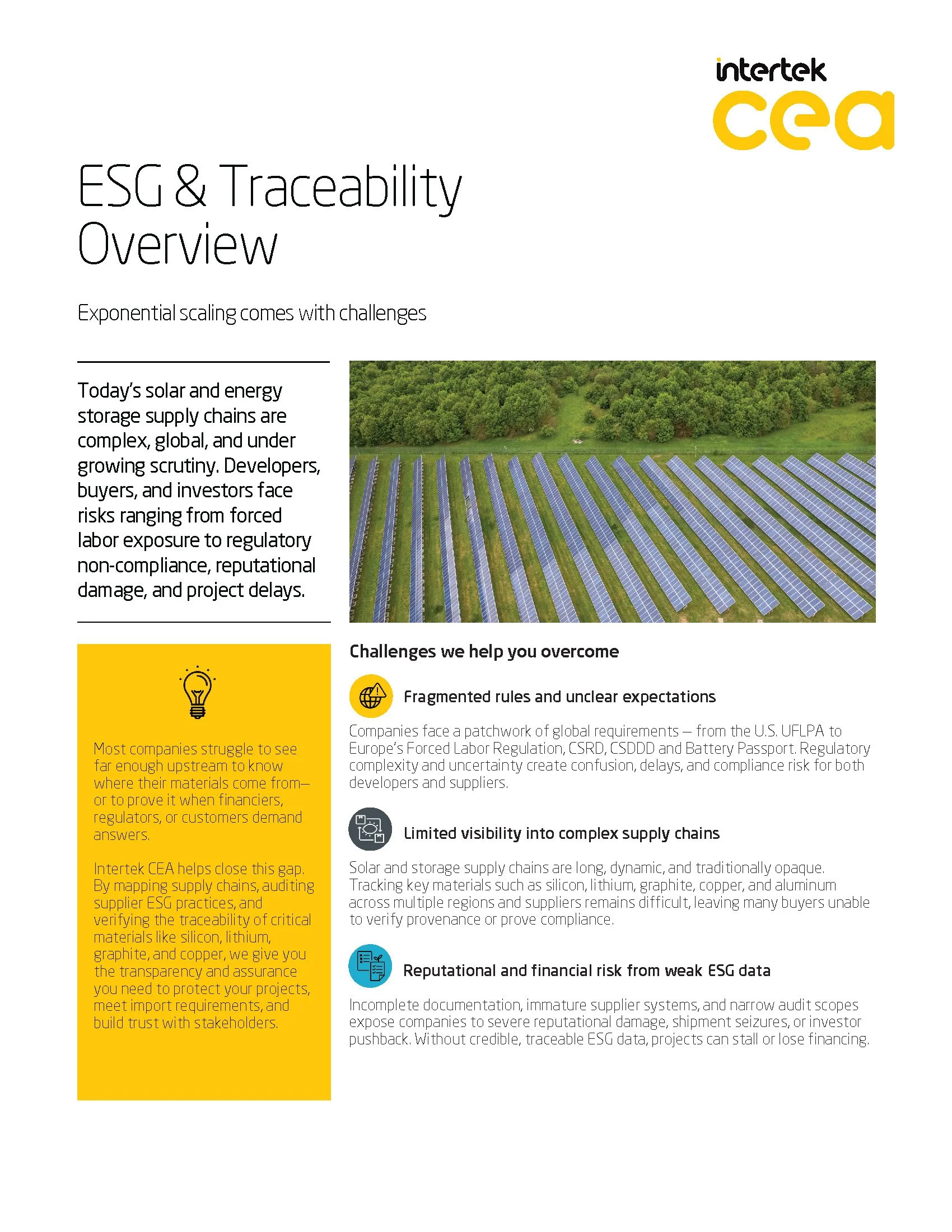

Mitigate supply chain risk and uncertainty with full-component supply chain traceability audits

Our rigorous traceability program reaches upstream all the way to the source of the raw materials – even up to the mine – and covers key components such as polysilicon, lithium, graphite, copper and aluminum. Combined with independent audits of suppliers’ own codes of conduct, this approach empowers importers to be best equipped to meet local import laws by documenting the provenance of key materials.

Robust third-party audits for supply chain transparency

Every day, Intertek CEA’s solar and energy storage experts are in factories globally conducting on-the-ground audits and providing industry-leading data about supply chains and raw materials from manufacturers.

Our Traceability Audits include:

Supply Chain Mapping

We perform a desktop evaluation to screen supplier risks in terms of geography, reputation and trade compliance across their entire supply chain.

The audit includes reviewing direct and indirect relationships of sub-suppliers along the various levels and nodes upstream, presence of factories and suppliers in regions of concern, and inclusion in entity lists.

Onsite Traceability Systems Audit

We perform an onsite audit to check the supplier’s traceability system through checks of standard operating procedures, systems and specialized software, as well as historical records.

The audit areas include purchasing, warehousing, production, and packaging for shipment. Sample products are selected, and traceability records are reviewed thoroughly.

Production Traceability Audit

During production, samples are selected to check that the raw materials used across the full supply chain of is traceable and matches the approved supply chain of the client’s project. Suppliers submit the agreed evidence to Intertek CEA to verify that production meets supply chain requirements.

This activity can be aligned with Quality Assurance sampling (pre-shipment inspection for PV modules or FAT for BESS). Shipment batches can be subject to traceability and certified for shipment.

Post-Production Traceability Audit

For already produced or installed PV or BESS plants, Intertek CEA can perform a post-production traceability audit, on a sampling basis, provided that the manufacturers can supply the required documentation.

Intertek CEA is a leader in traceability:

Have a Question or Need Assistance?

-

Supply Chain Traceability

Intertek CEA is among the first companies to become approved assessors by the Solar Stewardship Initiative (SSI).

Intertek CEA co-wrote SEIA’s Traceability Protocol – the de-facto guide for solar importers – our traceability audits follow SEIA’s Protocol which recommends controls such as:

Independent, third-party audits applied to internal processes and third-party suppliers

Corporate social responsibility codes of conduct

Security measures to safeguard information and prevent tampering of goods

Due diligence and monitoring of suppliers

Compliance programs

Trainings of employees

Evaluation of policies and procedures along with corrective action plans

Intertek CEA contributed to SolarPower Europe’s (SPE) Solar Sustainability Best Practices Benchmark Report. The report covers a wide range of topics including:

Carbon footprints

Circularity

Sustainable Supply Chains

Biodiversity in Large Scale Solar

Planning and Designing for Public Acceptance

Human Rights

Supply Chain Transparency