How to Make the Right Inspection Decisions for Solar Assets: From the Factory to the Field

Learn how and when to deploy electroluminescence (EL) testing effectively, why linking field and factory inspection data is critical, how AI tools can be used to detect and highlight quality issues, and more. Experts from Intertek CEA and AePVI explore how developers, EPCS and investors can implement a testing and inspection program that is tailored to the specific needs of their PV plant.

Each PV plant has its own specific needs and this pv magazine Webinar explains how to choose the right inspection method for the job.

Jörg Althaus of Intertek CEA and Andreas Fladung of AePVI explore how modern inspection technologies and strategies, including advanced EL testing and AI-powered analytics, are helping bridge the gap between manufacturing quality control and real-world field performance.

You will learn about the questions developers, EPCs and investors should be asking before deploying EL testing and other inspection methods at their PV plant.

The interactive discussion also explores why visibility of module quality is frequently lost after shipment, how inspection strategies are evolving across commissioning and operations, and how to align inspection methods with actual business risk. Experts discuss practical lessons from the field and how asset owners, developers, and EPCs can think more strategically about long-term asset value.

pv magazine webinar content:

Selecting the right inspection method

Use cases for EL inspection

Factory vs. Field EL: why comparison matters

When to use a drone

AI-based defect detection

Common market misconceptions

Real-world case studies

Q&A

What you’ll learn:

The right questions to ask before commissioning an inspection

Practical frameworks for inspections

What different technologies can (and can’t) detect

How a factory-to-field approach can improve quality assurance

How to generate inspection data that stands up to external scrutiny

In this pv magazine Week Europe webinar, experts from Intertek CEA and AePVI explore how developers, EPCS and investors can implement a testing and inspection program that is tailored to the specific needs of their PV plant.

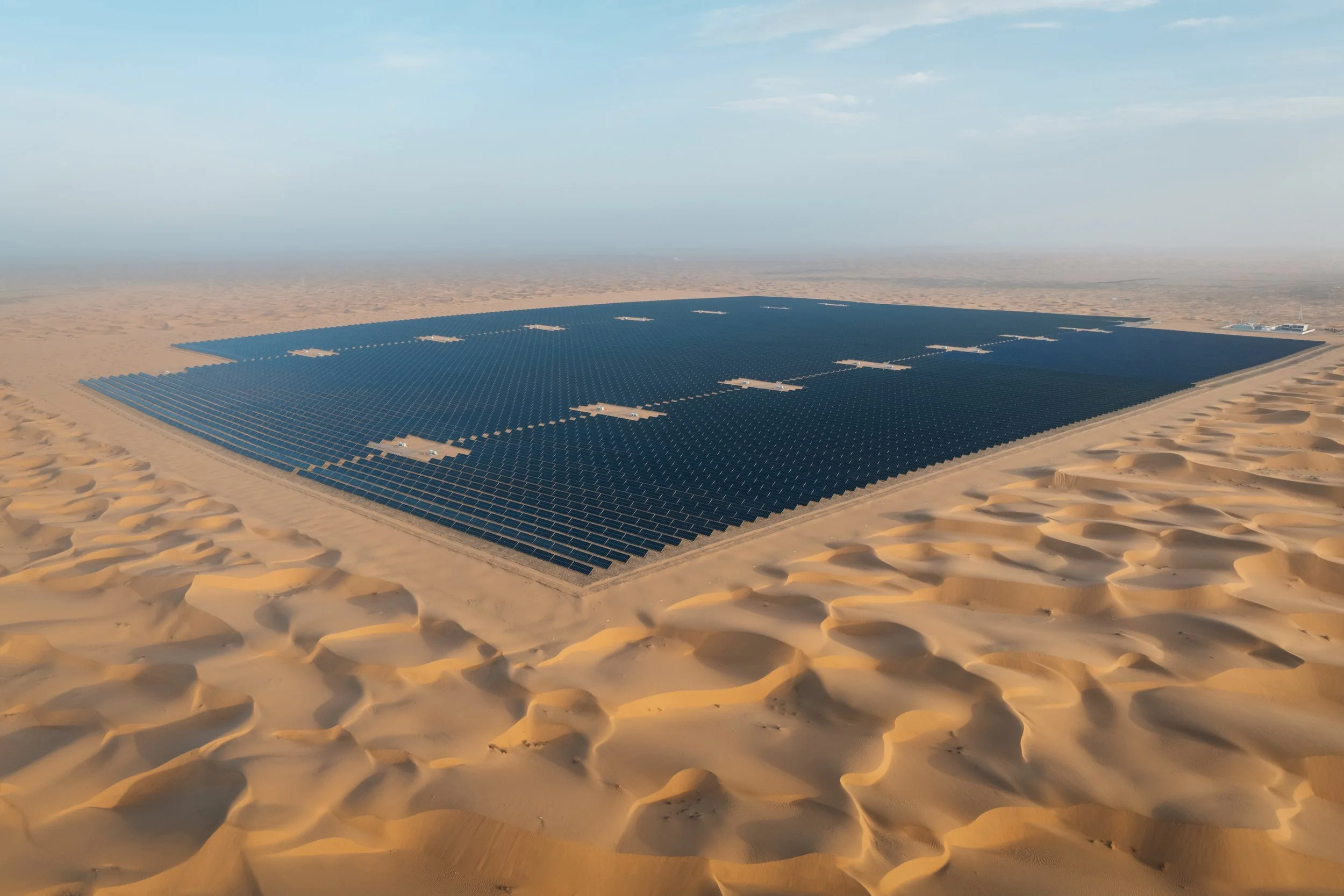

pv magazine: Jörg Althaus and Huatian Xu detail how the Middle East’s rapid solar expansion is shaped by both aggressive local-content industrial policies and the region’s uniquely harsh desert conditions.

PV Tech: Joerg Althaus, Intertek CEA’s Director of Engineering Services and Quality Assurance, warns that racking complexity, corrosion, evolving supply chains, and rising glass breakage risks pose growing challenges to solar PV projects.

pv magazine: Jörg Althaus of Intertek CEA and Andreas Fladung of Aerial PV Inspection highlight how electroluminescence (EL) testing — including drone-based approaches — can uncover microcracks, early degradation, and installation-related damage.

pv magazine: Intertek CEA's engineering experts highlight how overlooked site-specific challenges such as poor soil conditions, flash floods, complex terrain, and extreme wind loading in Southeast Asia can derail solar projects if not addressed early through rigorous engineering and civil due diligence.

pv magazine: Solar modules are growing larger, thinner, and more powerful—but a recurring issue is emerging worldwide: broken glass. According to Intertek CEA’s Joerg Althaus, these cracks often start near the frame or clamps and can spread from a few panels to thousands, without any obvious cause like hail or mishandling.

As solar deployments continue to grow, so do the risks of module failures, underperformance, and safety hazards—many of which are preventable with the right knowledge. In this Solar Power World webinar, Intertek CEA Senior Engineering Managers Claire Kearns-McCoy and Ankil Sanghvi explain how understanding common pitfalls—from thermal events to electrical failures—can help developers avoid millions in losses.

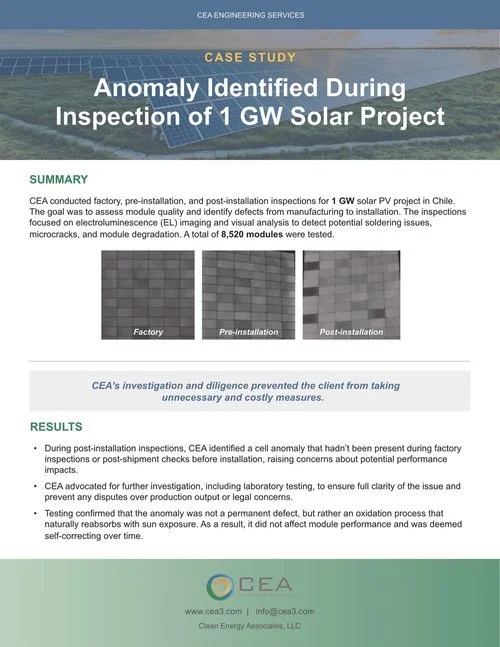

CEA conducted factory, pre-installation, and post-installation inspections for 1 GW solar PV portfolio in Chile. The goal was to assess module quality and identify defects from manufacturing to installation. The inspections focused on electroluminescence (EL) imaging and visual inspection to detect potential soldering issues, microcracks, and other module degradation mechanisms. A total of 8,520 images were taken.

A solar project developer engaged CEA to investigate widespread glass breakage across multiple PV sites. CEA conducted comprehensive on-site inspections and structural assessments, which pointed to possible issues related to module durability and mounting system compatibility.

This case study explores a thermal event inspection carried out by Clean Energy Associates (CEA) at a rooftop solar PV installation. CEA found the access to the roof was unsecured that allowed unauthorized cleaning of the site prior to the start of the investigation.

Claire Kearns-McCoy and Paul Wormser consider the lasting impact of a May 2019 hailstorm that damaged 400,000 solar panels in Texas.

In this webinar hosted by the American Solar Energy Society's PV Technical Division, CEA's Engineering Manager Claire Kearns-McCoy discusses solar PV module quality risks.

CEA’s Vice President of Marketing, Jake Edie, recently wrote an article in Renewable Energy World about the most surprising findings in clean energy and what developers and buyers will be watching most closely as 2024 unfolds.

After years of improving quality standards, solar cell cracking appears to be on the rise again, perhaps due to new manufacturers entering the sector. Clean Energy Associates’ (CEA) senior engineering manager Claire Kearns-McCoy considers ways to stop the rot.

Intertek CEA's extensive field research unveils the hidden threats in solar PV modules, emphasizing the critical role of Electroluminescence (EL) testing in detecting unseen damages. Our findings highlight the lifecycle of module defects, the surge in microcracks, and the pivotal importance of visual inspections in identifying issues often missed by other methods.

Uncover the truth about solar rooftop safety. Download Intertek CEA's report, learn common risks, and strategize remediation.

pv magazine Roundtables USA included this presentation by CEA’s Senior Project Manager/Solar Engineer, Claire Kearns-McCoy on the importance of using EL imaging to ensure PV module quality.